Ni CATALYST (CLAUSE REACTOR CATALYST)

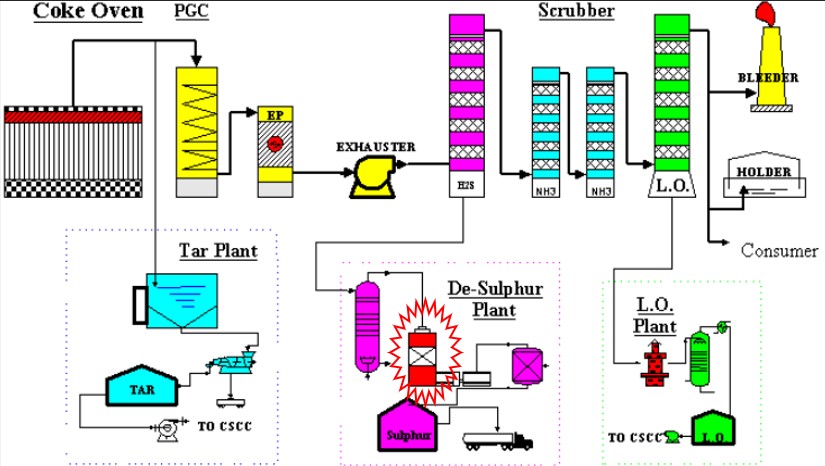

HIMAG-CAT1 catalyst is used in the coke oven gas purification and recovery system of coking plants. It serves to decompose the ammonia (NH3), hydrogen cyanide (HCN), and some hydrocarbons present in the acidic gas in the pipeline at high temperatures. Possessing certain functional characteristics that make it suitable for the aforementioned coke oven gas purification and recovery system.

Features

(1) Excellent chemical activity, enhancing the efficiency of ammonia decomposition under reactive conditions.

(2) Can withstand high temperatures in the reactor (up to 1300°C).

(3) Can endure an airflow impact of 1.2kg/cm2 within the reactor.

(4) Has a favorable stacking structure; a stacking height of 2m has a pressure drop of less than

100mmHg, ensuring no airflow blockage.

(5) ✶Compared to other competitors, the catalysts produced by Himag possess excellent

mechanical strength, preventing them from breaking when filled into reactors. Even

after extended use, they don't easily crumble into powder, which could lead to equipment

blockage. This allows for longer usage periods, and when replacement is necessary, less time is needed for handling.

Figure 1.Appearance of HIMAG-CAT1

Figure 2. Microstructure of HIMAG-CAT1

Form (Dimensions) : (18±2)mmψ x (18±2) mm L yellowish-brown cylinder

Carrier:Magnesite

Active Component:>6 wt% Nickel

Bulk Density:1.55 ± 0.05 kgs/l

Crushing Strength:Minimum spec 250 kgf,typical value 350kgf

Operating Temperature:Up to 1300℃

Thermal Stability:Above 1350℃, Ni component becomes volatile and is released from the carrier leading to irreversible reduction in activity.

Catalytic Efficiency:>99% at Coal Chemical Plant in China

Steel Lifetime:up to 5 years